information Center

Common problems and solutions of slewing bearings (Part 2)

- 2022-02-09 00:41:00

ShakeAfter the slewing bearing is loaded, its clearance is about 3-5 times that of the factory inspection (three-point inspection method), and it can continue to be used within this range.(1) The mounting bolts are loose, causing shaking during work. Immediately check all inner and outer ring mounting bolts and tighten as required.(2) The rigidity of...

learn more

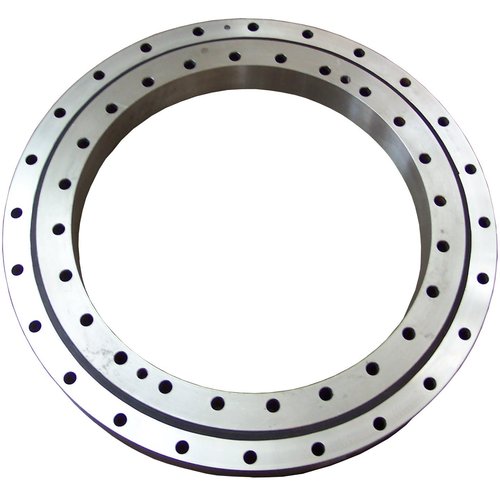

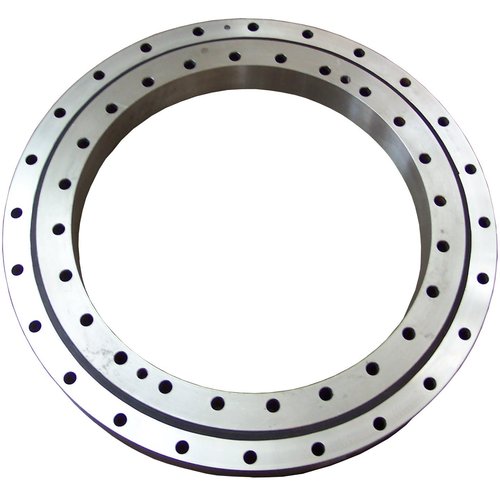

What is the difference between slewing bearings and general bearings?

- 2021-07-15 07:03:00

1. The size of the slewing bearing is large, and its diameter is usually 0.4-10 meters2. The slewing bearing generally bears axial force, radial force, and a large overturning moment.3. The running speed of the slewing bearing is low. In many occasions, the slewing bearing only rotates back and forth within the angle.4. Usually, the slewing bearing i...

learn more

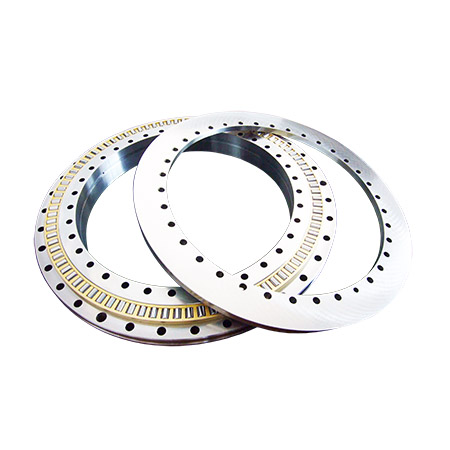

What are the materials usually used for slewing bearings?

- 2021-06-03 00:08:00

1. Ring and rolling element materialIn general, hard carbon chromium bearing steel is used as a whole for slewing bearing rollers. Manufactured from grade GCr15 or GCr15SiMn steel; turntable bearing caps are made of case hardened steel, usually 50Mn steel, but other brands of case hardened steel can sometimes be selected to meet the host requirements...

learn more

Type selection of slewing bearing

- 2021-05-13 04:10:00

When the swivel support is used under overload conditions, it may become stuck.At this time, the body can be tilted by means of lateral amplitude, adjusting the outriggers or moving the position of the chassis, so as to help realize the rotating motion of the heavy object and complete the predetermined lifting and other operations.If the swivel suppo...

learn more

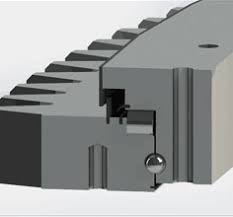

Standard for replacement of slewing bearing seal strip

- 2021-04-16 08:13:00

1. Clean the installation groove of the sealing strip and remove the oil;2. Prepare the qualified sealing strip according to the length required by the original factory, and prepare a 502 connector;3. With the flat-blade screwdriver, slightly stretch the sealing strip to the appropriate length and install it in the groove;4. The interface is cut into...

learn more