information Center

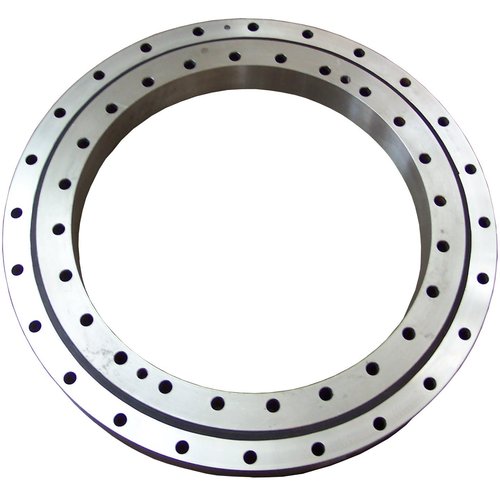

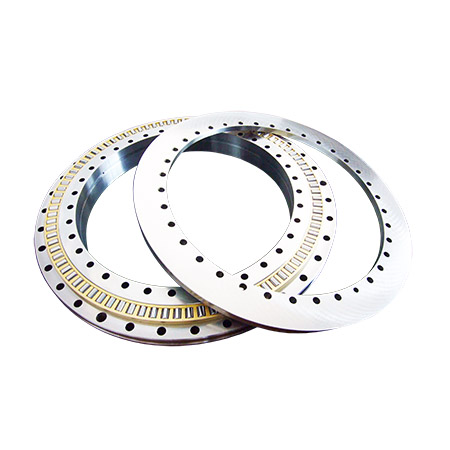

Common problems and solutions of slewing bearings (Part 2)

- 2022-02-09 00:41:00

ShakeAfter the slewing bearing is loaded, its clearance is about 3-5 times that of the factory inspection (three-point inspection method), and it can continue to be used within this range.(1) The mounting bolts are loose, causing shaking during work. Immediately check all inner and outer ring mounting bolts and tighten as required.(2) The rigidity of th...

learn more

Common problems and solutions of slewing bearings (Part 1)

- 2022-01-13 04:45:00

Broken toothReasons:(1) The backlash of the large and small gears is improperly adjusted during installation.(2) Failure to adjust the meshing clearance with the pinion at the maximum position of the tooth jump as required, resulting in a stuck and broken tooth during operation.(3) The axes of the large and small gears are not parallel or the mounting b...

learn more

Lubrication Oil of Slewing bearing

- 2021-11-16 09:45:00

It is a special lubricating oil for the spindle bearings of precision machine tools and similar equipment, also known as bearing oil.Its main performance:1. Appropriate viscosity and good viscosity-temperature characteristics.2. Good lubricity.Maintaining good lubricating performance plays a role in reducing friction and friction heat, reducing the temp...

learn more.jpg)

How to maintain crane slewing bearing?

- 2021-10-20 08:45:00

First of all, pay attention to the danger of being dragged into the rotary pinion, crushing and shearing. During inspection and maintenance, make sure that repair workers are not in the danger zone between the main boom, the loading vehicle and the roller.Next, check the slewing bearing bolts1. The crane needs to regularly check the bolts on the slewing...

learn more.jpg)

How to maintain crane slewing bearing?

- 2021-10-20 08:45:00

First of all, pay attention to the danger of being dragged into the rotary pinion, crushing and shearing. During inspection and maintenance, make sure that repair workers are not in the danger zone between the main boom, the loading vehicle and the roller.Next, check the slewing bearing bolts1. The crane needs to regularly check the bolts on the slewing...

learn more